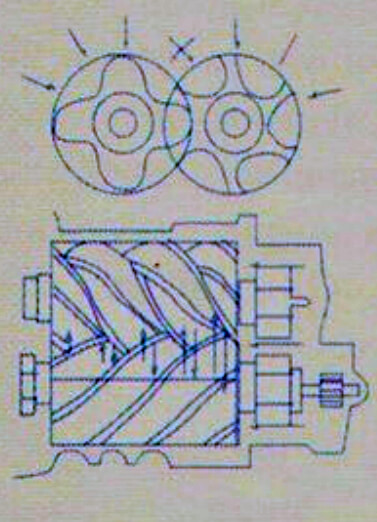

Working Principle of Single Screw Air Compressor

The air compressor air end is composed of one cylindrical worm and two symmetrical plane star wheels, which are engaged and mounted in a casting. The worm groove, casting and the tooth surface form a sealed cavity. The worm rotates the star wheels. When the star wheels moving in the worm groove, the air in the groove is compressed and exhausted. The worm has 6 grooves and is separated horizontally by two star wheels into two working cavities, each of which realizes separately suction, compression and exhaustion. Therefore, one single screw air compressor equals one unit six double cylinder piston compressor

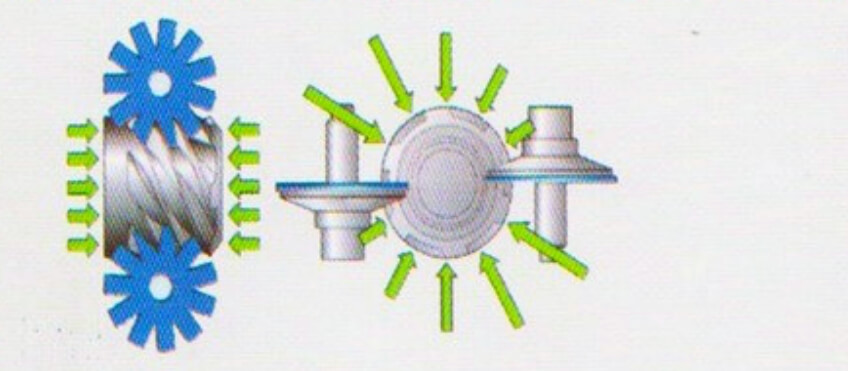

Single Screw Air Compressor Forces llustration

The axial and radial forces on worm can not be completely balanced

Double Screw Air Compressor Forces lustration

The axial and radial forces on worm can not be completely balanced

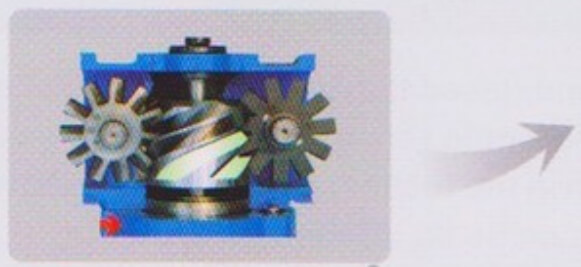

Suction

When the tooth grooves on suction end of worm al connect with suction cavity they are all in the state of suction.When the worm rotates to certain position and tooth groove cavity is separated from cavity by the engagement with convex tooth of star wheel suction ends

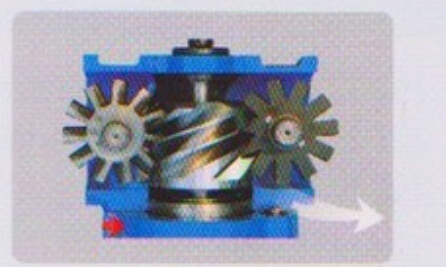

Compression

As the worm continues to rotate and the basic unit volume begins to decrease with the advancement of convex tooth of star wheel along the tooth groove of screw rod, the compression is realized

Exhaustion

When basic unit volume connects to the outlet, the compressed air with certain pressure is sent to exhaustion pipe by the continuous rotating worm